Poplar Plywood: Made, Properties and Uses

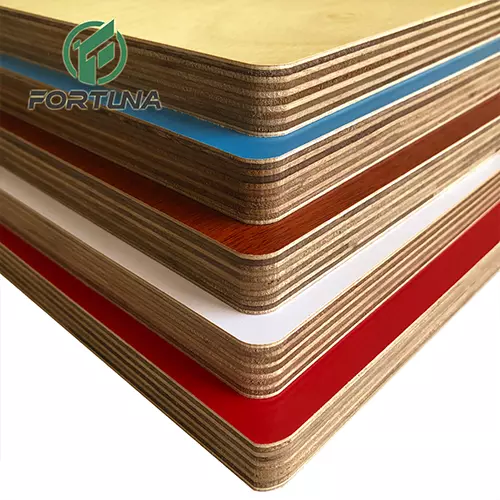

Poplar plywood is celebrated in woodworking and construction circles for its lightweight properties, versatility, and affordability. Originating from the poplar tree, this plywood offers a smooth finish and is a popular choice in furniture, cabinetry, and DIY projects due to its workability and natural appeal. In this comprehensive guide, we’ll delve into everything you need to know about poplar plywood, from its various types to its numerous applications, maintenance tips, and more. What is Poplar Plywood? Poplar plywood is an engineered wood product made by layering thin sheets (veneers) of poplar wood, which are glued together with alternating grain patterns to enhance strength and durability. This construction method not only makes it sturdy but also offers a stable and flat surface ideal for woodworking. The plywood is light in color, has a uniform grain, and is frequently used in applications where a smooth, paintable surface is desired.Poplar plywood stands out for its ability to be easily cut, sanded, and finished, making it a favorite in cabinetry, furniture making, and indoor projects. It’s less expensive than other hardwood plywood types, yet provides sufficient durability for a wide range of projects, from simple DIY crafts to complex cabinetry and decorative paneling. Standard Poplar Plywood This is the most commonly used form of poplar plywood, suitable for a wide range of interior applications. Standard poplar plywood is lightweight, easy to handle, and offers a consistent surface that can be painted, stained, or varnished. Flexible Poplar Plywood Flexible poplar plywood, also known as bendy plywood, is designed for curved applications such as furniture with rounded edges, decorative wall panels, and custom installations. This plywood type can be bent easily without cracking, making it ideal for intricate designs and projects requiring a flexible wood base. Marine Poplar Plywood Marine-grade poplar plywood is specially treated to be moisture-resistant, making it suitable for environments where water exposure is common. While not as water-resistant as marine plywood made from hardwoods, marine poplar plywood is a good option for lower-budget water-resistant needs such as boat interiors, bathroom vanities, or damp basements. How Poplar Plywood is Made The production of poplar plywood involves a series of steps, from sourcing the wood to the final pressing and finishing processes. Sourcing and Preparing Poplar Wood The poplar wood used for plywood typically comes from fast-growing poplar trees, known for their straight trunks and consistent grain. These trees are often grown in managed forests, making them a more sustainable option. Manufacturing Process Once the wood is harvested, it is cut into thin veneers and dried to remove moisture. The dried veneers are then layered with adhesives, with each layer positioned at a right angle to the previous one. This cross-graining technique strengthens the plywood and minimizes warping and shrinking. After layering, the plywood is pressed under high pressure and heat to cure the adhesive, resulting in a sturdy, flat sheet of poplar plywood. Characteristics and Properties of Poplar Plywood Poplar plywood boasts a range of properties that make it ideal for various applications. Here are some of its key characteristics: Lightweight Yet Durable Poplar plywood is lighter than many other hardwood plywoods, making it easier to handle and ideal for furniture that may need to be moved. Despite its lightweight, it maintains good structural integrity, holding up well in furniture and cabinetry applications. Smooth Finish and Paintability One of the standout features of poplar plywood is its smooth, even surface. It sands easily, providing an excellent base for painting, staining, or veneering. The smoothness of poplar plywood is especially valued in furniture making and interior decor. Eco-Friendly and Sustainable Option Because poplar trees grow quickly and are widely available, poplar plywood is considered a more sustainable choice compared to slower-growing hardwoods. Additionally, responsibly sourced poplar plywood reduces the impact on old-growth forests and contributes to eco-friendly practices in construction and woodworking.