Types of Adhesives and Resins Used in OSB

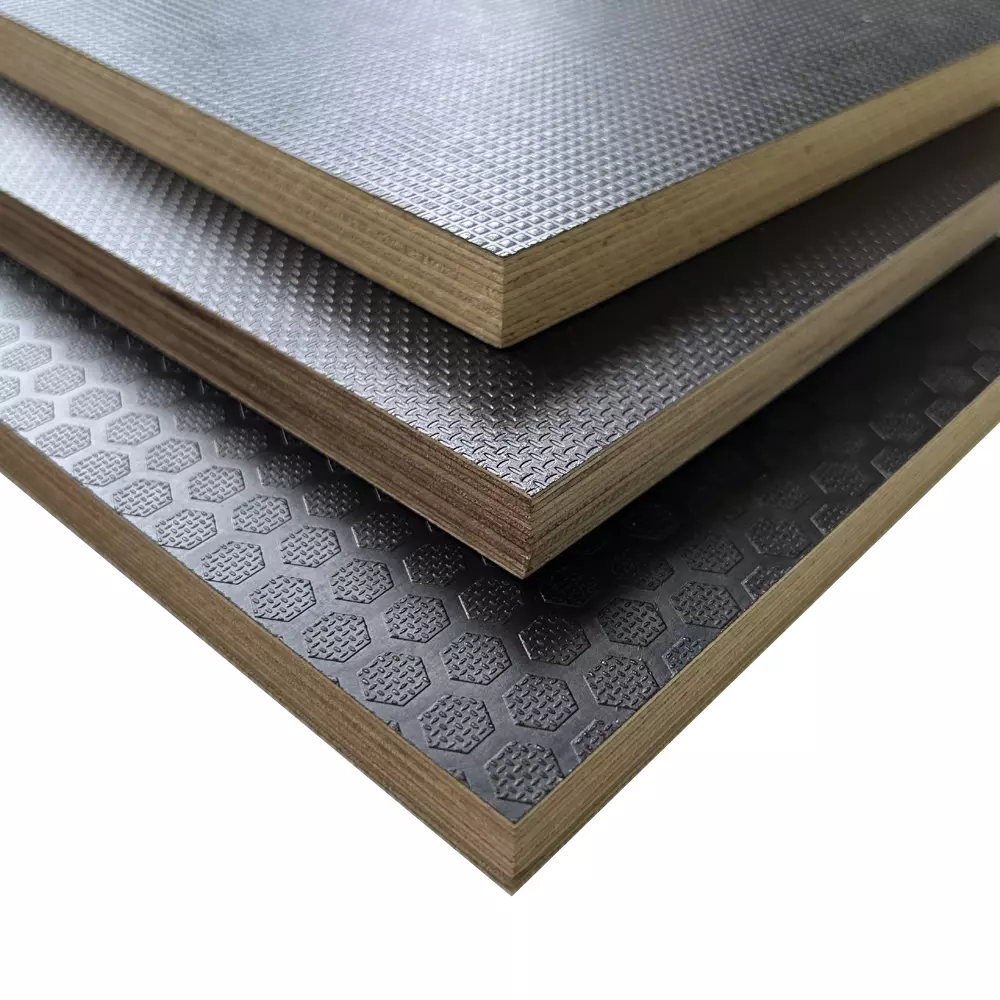

BLOG HOME >> BLOG The adhesives and resins used in the production of OSB are critical to the board’s performance characteristics. Different types of resins are used depending on the intended application of the OSB, ranging from non-structural to highly durable, water-resistant types suitable for exterior use. Urea-Formaldehyde Resin: This adhesive is commonly used in non-structural OSB (OSB/1 and OSB/2). Urea-formaldehyde provides good bonding strength but is not resistant to moisture, making it unsuitable for use in environments where the OSB might be exposed to water. Isocyanate-Based Glues (PMDI): Poly-methylene diphenyl diisocyanate (PMDI) is used in the inner layers of structural OSB (OSB/2 and OSB/3). It provides excellent bonding strength and enhances the board’s overall durability. PMDI is also resistant to moisture, which is crucial for OSB used in load-bearing applications. Melamine-Urea-Formaldehyde (MUF) Resin: Used in combination with other resins, MUF is applied to the surface layers of OSB to improve water resistance. This resin is often found in OSB/2 types, where some level of moisture exposure is expected. Phenol Formaldehyde Resin: This is the resin of choice for high-performance structural OSB (OSB/3 and OSB/4). Phenol formaldehyde is highly resistant to moisture and can withstand harsh environmental conditions, making it ideal for OSB used in exterior applications. Each adhesive type has its advantages and limitations, influencing the suitability of the OSB for different applications. The choice of resin not only affects the board’s strength and moisture resistance but also has implications for environmental and health concerns, particularly in relation to formaldehyde emissions. Classification of OSB Types OSB is classified into different types based on its intended use, with each type offering varying levels of strength, moisture resistance, and durability. Understanding these classifications is essential for selecting the right OSB for specific applications. OSB/1: This is a non-structural OSB type used in dry conditions. It is suitable for interior applications such as furniture or packaging but is not designed to bear loads or withstand moisture. OSB/2: Structural OSB for dry conditions, this type is used in load-bearing applications such as wall sheathing and subflooring. OSB/2 can handle some exposure to moisture, but it is not recommended for use in damp environments. OSB/3: This type is designed for structural use in humid conditions. OSB/3 is commonly used in roofing and exterior wall sheathing where moisture resistance is critical. It can be exposed to the elements for limited periods during construction. OSB/4: The most durable and moisture-resistant type, OSB/4 is used in high-performance structural applications. It is suitable for both interior and exterior use, particularly in areas with high humidity or direct exposure to weather. The classification of OSB types helps builders and contractors select the appropriate material based on the specific requirements of their project. It ensures that the OSB used will perform well under the expected conditions, providing long-lasting and reliable structural support. BlOG Whatsapp Youtube Facebook X-twitter Instagram