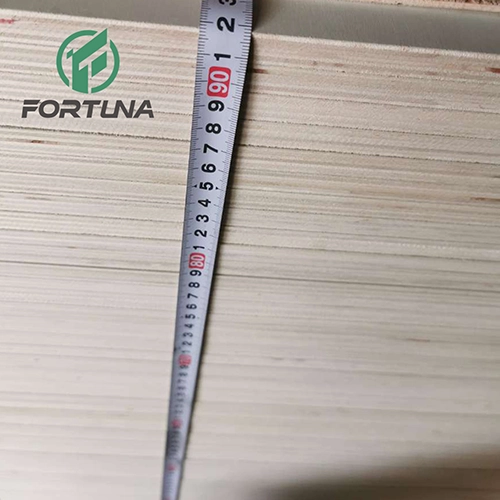

Poplar plywood is a versatile and widely used material, known for its lightweight, strength, and ease of use. It is made from layers of poplar wood veneer, which are glued together to form a sturdy yet flexible panel. There are several types of poplar plywood, each tailored to specific applications and needs. Below are the three main types of Poplar plywood: Standard Poplar Plywood, Flexible Poplar Plywood, and Marine Poplar Plywood.

Standard Poplar Plywood

Standard Poplar Plywood is the most common and widely available type of poplar plywood. It is made using layers of poplar veneer that are bonded together, typically with an adhesive that provides a strong and durable result. Standard poplar plywood is known for its smooth surface, lightweight nature, and ease of handling, making it a popular choice for a wide range of applications.

Key features of standard poplar plywood:

Lightweight: Poplar is one of the lightest hardwoods, making standard poplar plywood easier to handle and transport.

Smooth Surface: The surface of standard poplar plywood is often smooth, making it ideal for applications where the appearance is important, such as in cabinetry, furniture making, and interior panels.

Strength and Stability: Despite its light weight, standard poplar plywood maintains good strength and stability for most residential and commercial applications.

Cost-Effective: Compared to other hardwood plywood options, standard poplar plywood is relatively affordable, making it a cost-effective choice for projects that require large quantities of material.

Standard poplar plywood is ideal for projects like furniture making, shelving, and paneling, where a smooth, lightweight, and stable material is required.

Flexible Poplar Plywood

Flexible Poplar Plywood is a specialized type of poplar plywood designed for applications that require bending or shaping. This plywood is made using a thinner veneer, allowing it to be more pliable and flexible without sacrificing strength or stability. It is commonly used for projects that involve curved or rounded surfaces, where standard plywood might be too rigid.

Key features of flexible poplar plywood:

Bendable and Malleable: Flexible poplar plywood is easy to curve or bend, making it suitable for creating rounded or curved shapes, such as in furniture, boat building, or interior design.

Thin Layers: The thin veneers used in flexible poplar plywood give it its flexibility, allowing it to be shaped to fit various contours and forms.

Strong yet Lightweight: Like standard poplar plywood, it is lightweight but still offers enough strength to support various applications.

Easy to Work With: Flexible poplar plywood is relatively easy to cut, shape, and finish, which makes it a favorite for artisans and designers working on custom pieces.

Flexible poplar plywood is often used in the production of curved furniture, boat interiors, and architectural features, such as curved panels, archways, or custom cabinetry.

Marine Poplar Plywood

Marine Poplar Plywood is a high-performance version of poplar plywood designed specifically for use in environments exposed to moisture or water. This type of plywood is treated with special adhesives that make it more resistant to water, mold, and rot, which are common concerns in marine environments or areas with high humidity.

Key features of marine poplar plywood:

Water-Resistant: Marine poplar plywood is made with waterproof adhesives and treated wood veneers, making it resistant to water damage, rot, and mildew. It is ideal for use in boat building, docks, and other water-exposed structures.

Durable and Strong: This plywood type is built to withstand harsh conditions, maintaining its strength and integrity even when exposed to moisture and fluctuating temperatures.

Specialty for Marine and Outdoor Use: While standard poplar plywood may not hold up in wet conditions, marine poplar plywood is specifically engineered for these environments, ensuring longer-lasting durability.

Heavy-Duty Applications: Marine poplar plywood is often used for applications such as boat hulls, marine furniture, outdoor cabinetry, and other structures where moisture resistance is critical.

Marine poplar plywood is ideal for boat building, docks, outdoor structures, and any application where exposure to water or high humidity is a concern.

Poplar plywood is a versatile and cost-effective material with a range of specialized types to suit different needs. Standard Poplar Plywood is perfect for general indoor applications like furniture and paneling, offering a smooth surface and lightweight design. Flexible Poplar Plywood offers the added benefit of bendability, making it ideal for curved shapes and custom projects. Finally, Marine Poplar Plywood provides exceptional moisture resistance, making it perfect for outdoor and water-exposed applications like boat building and marine construction. Understanding the differences between these types of poplar plywood allows you to choose the right material for your specific project, ensuring durability, functionality, and long-term performance.