Plywood Bark Cutting Method

It all comes down to the grain. Whether it’s red oak, maple or an exotic like anegre, a hardwood’s grain is responsible for its unmistakable beauty and appeal. Which means consistency and qualitly are paramount when it comes to producing hardwood veneers. That’s why Timber Products uses four unique processes to produce a range of wood patterns that are graded and sorted by hand, ensuring a reliable grain pattemn on each and every panel.

Rotary

The log is centered in the lathe and tumed against a knife blade at a slight angle following the log’s annular growth rings, producing a multi-patterned grain veneer.

Ideal for: Large surface applications where a broad grain pattern will suffice. Rotary cut sheets are generally less expensive than sliced veneer and can yield whole piece face sheets.

Quarter Slicing

Produces a narrow, striped grain veneer where the growth rings of the log strike the blade at approximately right angles. Some species will create a series of straight stripes, while others’ stripes may be varied in angle and length, Red and white oak produce a pronounced flake pattern when quarter sliced, while mahogany creates a ribbon stripe pattern.

Ideal for: Mission-style or other applications requiring a unifomm appearance with generous ray flaking. More cost-effective than rift-cutting.

Rift Cut

Produces a rift or comb grain effect similar to that of quarter slicing, but generally is only used with red and white oak. This process minimizes ray flake as the log is cut at an angle of about 16 percent off the quartered position.

Ideal for: An application calling for unifomm white or red oak appearance without ray flake. Generally higher in cost due to low yields.

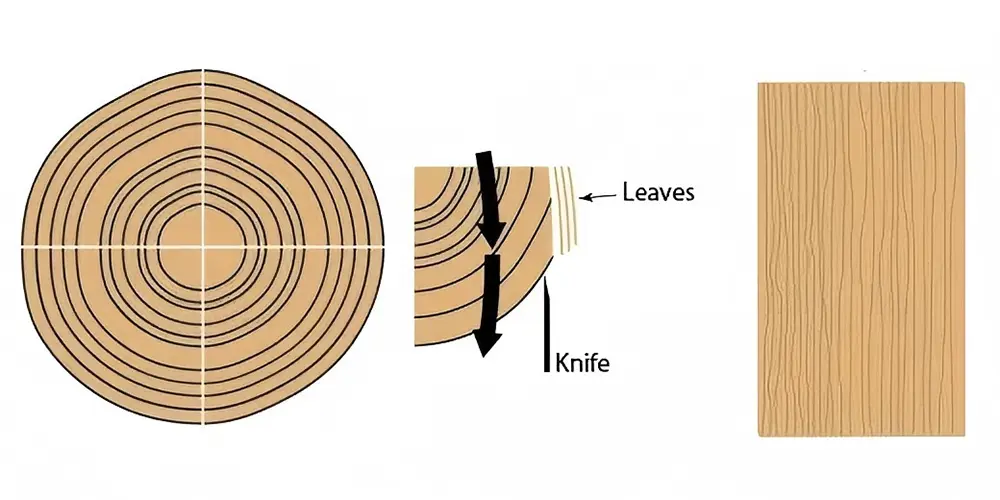

Plain Slicing or Flat Cut

The most common slicing method that produces a distinct cathedral grain veneer. A half log, or flitch, is mounted so that the veneer is cut along the growth rings, parallel to a line through the center of the log.

Ideal for: Any application where an eye-catching paltem is desired at an affordable cost; of the slicing methods, plain slicing is the least expensive.

More Support

Packaging & Delivery

How to quickly and safely deliver the Plywood products you ordered to the designated location? You can choose from the following methods.

Packaging & Delivery

How to quickly and safely deliver the Plywood products you ordered to the designated location? You can choose from the following methods.

Plywood Core

In order to adapt to different working scenarios, we provide the following plywood cores for you to choose.

Plywood Core

In order to adapt to different working scenarios, we provide the following plywood cores for you to choose.

Glue Types

In order to adapt to different environments and scenarios, we provide a variety of plywood glue for you to choose.

Glue Types

In order to adapt to different environments and scenarios, we provide a variety of plywood glue for you to choose.

Plywood Certificate

To give you more peace of mind, we have obtained a variety of certifications to meet your needs.

Plywood Certificate

To give you more peace of mind, we have obtained a variety of certifications to meet your needs.