Table of Contents

When you’re knee-deep in a renovation, cabinetry job, or commercial fit-out, choosing the right substrate can make or break your timeline, budget, and final finish. Enter Medium Density Fibreboard—or MDF, as it’s commonly known. But what exactly is it, and why does it keep showing up on your material spec sheets?

Let’s cut through the jargon and get practical.

What Is Medium Density Fibreboard?

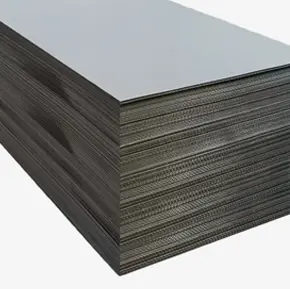

Medium Density Fibreboard is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and a resin binder, and forming panels under high temperature and pressure. The result? A smooth, uniform board with no knots, grain patterns, or voids—ideal for painting, laminating, or precision machining.

Compared to plywood or solid wood, MDF offers superior dimensional stability and surface consistency. That’s why it’s a go-to for everything from retail displays and office furniture to skirting boards and speaker cabinets.

But not all MDF is created equal. Depending on your project’s environment and performance requirements, you might need specialized variants.

Moisture-Resistant MDF: When Humidity Can’t Be Avoided

Standard MDF swells when exposed to moisture—so bathrooms, kitchens, or exterior-adjacent zones demand something tougher. Moisture-Resistant MDF (often green-tinted for easy identification) contains additives that significantly reduce water absorption.

This doesn’t mean it’s waterproof—it’s still not suitable for direct outdoor use—but it holds up far better in damp conditions. Think utility rooms, laundry areas, or even humid climates where condensation is a concern.

Always seal edges and surfaces with a quality primer or sealant, even with MR-MDF. It’s cheap insurance against long-term damage.

Fire-Rated MDF: Safety Without Sacrificing Finish

In commercial builds—especially schools, hospitals, or multi-residential projects—fire safety isn’t optional. Fire-Rated MDF is treated with flame-retardant chemicals that slow ignition and reduce smoke emission during a fire. These boards meet stringent standards like EN 13501-1 (Class B or better) or ASTM E84.

The best part? You don’t lose the smooth finish MDF is known for. Fire-rated versions machine and paint just like standard boards, making them ideal for wall panels, ceiling baffles, or reception desks where aesthetics and compliance must coexist.

High Density Fibreboard vs. MDF: Know the Difference

You might also hear about High Density Fibreboard (HDF). While similar in composition, HDF is denser (typically >800 kg/m³ vs. MDF’s 600–800 kg/m³), harder, and more durable. It’s often used for flooring underlays, door skins, or high-wear applications.

But here’s the catch: HDF is less forgiving to work with—harder on tools, more prone to chipping, and usually more expensive. For most interior joinery and cabinetry, standard or enhanced MDF strikes the right balance of performance and workability.

Why Project Professionals Choose MDF

- Consistent surface: No sanding surprises or grain tear-out.

- Cost-effective: Often cheaper than solid wood or high-grade plywood.

- Design flexibility: CNC routers love it—perfect for intricate profiles.

- Paint-ready: Absorbs finishes evenly for a flawless look.

Just remember: MDF is heavier than many alternatives, and dust control during cutting is non-negotiable (always wear PPE and use extraction).

Final Thoughts

Whether you’re specifying materials for a luxury hotel lobby or building custom shelving for a client’s home office, understanding the nuances of Medium Density Fibreboard—and its specialized forms—can save time, reduce callbacks, and deliver a higher-quality end product.

Don’t treat all MDF as interchangeable. Match the board to the environment, and you’ll avoid costly mistakes down the line.