Table of Contents

Understanding MDF in Modern Manufacturing

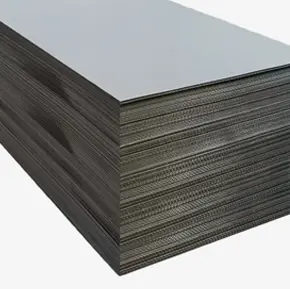

MDF—short for Medium Density Fiberboard—is one of today’s most widely used engineered wood materials. In the first 10% of this article, it’s important to highlight that MDF is created by breaking down softwood fibers, mixing them with resin, and pressing them into dense, smooth panels. For wholesalers and project-based customers, MDF offers consistency, affordability, and stable supply—qualities essential for long-term partnerships.

Unlike natural wood, MDF is highly uniform. It has no knots, grain inconsistencies, or internal gaps, making it ideal for CNC machining, router work, lamination, and large-scale production lines.

How MDF Is Made

The process includes:

- Fiber refining

- Resin blending

- Hot pressing

- Sanding

- Quality grading

These steps ensure stable density and a smooth surface suitable for premium finishing.

MDF vs Other Engineered Wood Products

MDF vs Plywood

- MDF is smoother and easier to rout

- Plywood is stronger in load-bearing applications

MDF vs Particleboard

- MDF is denser, stronger, and machines better

- Particleboard is cheaper but less durable

When to Choose MDF

Choose MDF when you need:

- Consistent texture

- High-quality finishing

- Clean, sharp edges

Key Technical Properties of MDF (Density, Strength, Moisture Resistance)

Standard MDF

Suitable for furniture, cabinets, partitions, displays.

High-Density MDF (HDF)

Used for flooring, interior doors, and high-performance applications.

Moisture-Resistant MDF (MR MDF)

Ideal for kitchens, bathrooms, and commercial interiors with high humidity.

Why MDF Is Popular Among B2B Buyers

For wholesalers and importers, MDF provides:

- Stable pricing that improves margin planning

- Reliable supply due to large global manufacturing capacity

- Low waste thanks to consistent density

- Easy processing that reduces labor time

For project contractors, MDF helps speed up installation and reduce finishing costs.

Common Industrial Applications of MDF

MDF is widely used across:

- Commercial furniture manufacturing

- Cabinets and wardrobes

- Interior wall panels

- Door skins and frames

- Retail store fixtures

- Acoustic panels

- Decorative elements for hotels & offices

Its versatility makes it a go-to choice for large-scale projects.

MDF Specifications Wholesalers Must Know

| Parameter | Typical Options |

| Sheet Size | 1220×2440mm / 1830×2440mm / Custom |

| Thickness | 2.5mm – 25mm |

| Density | 650–880 kg/m³ |

| Grades | Standard / HDF / MR / Fire-Rated |

Surface Types and Finishing Options for MDF

- Raw MDF: Suitable for painting and laminating

- Melamine MDF: Ready-made colors for cabinets and wardrobes

- Veneered MDF: Natural wood appearance with stable core

- PVC Laminated MDF: Durable and moisture-friendly

MDF for Large-Scale Projects and Contracting

Contractors value MDF because:

- It machines cleanly

- It doesn’t warp under stable indoor conditions

- It works perfectly with CNC cutting and shaping

- It supports mass production with minimal batch variation

Whether you’re delivering 500 hotel rooms or outfitting a commercial mall, MDF ensures uniformity.

MOQ, Lead Time & Logistics Considerations

Wholesalers typically order:

- FCL (Full Container Load) shipments

- 20GP, 40GP, or 40HQ containers

Lead times average 15–25 days, depending on finish and grade. Palletized or loose-loading options are available depending on exporter capabilities.

Environmental Standards and Certifications

Reliable MDF manufacturers comply with:

- CARB Phase II

- EPA TSCA Title VI

- E0/E1 Formaldehyde Standards

- FSC Certification (for sustainable forestry)

How to Choose a Reliable MDF Supplier

Look for:

- In-house testing equipment

- Quality control at each production stage

- Competitive MOQ options

- Transparent pricing

- Consistent density and bonding strength

Factory capacity also matters—larger mills offer more stable supply.

The Future of MDF in Global Markets

The demand for MDF continues to grow due to:

- Affordable housing projects

- Modern modular furniture

- Expansion of interior construction markets

Tech innovations—including waterproof MDF and fire-resistant MDF—are increasing adoption.

Using MDF to Improve Project Cost Performance

MDF helps reduce:

- Material waste

- Finishing time

- Edge treatment cost

- CNC machining expenses

This makes it a top choice for procurement managers aiming to control budgets.

Common Challenges & Practical Solutions with MDF

| Challenge | Solutio |

| Moisture issues | Use MR MDF / Seal edges |

| Edge deterioration | Use edge banding |

| Screw holding strength | Pre-drill holes / Use confirmat screws |

| Heavy weight | Choose lighter MDF variants |

FAQs About MDF

1. What is MDF mainly used for in B2B projects?

Furniture, cabinets, doors, retail fixtures, and interior panels.

2. Is MDF strong enough for commercial use?

Yes—commercial-grade MDF is dense and stable, perfect for professional projects.

3. Can MDF be used in humidity-prone areas?

Yes, but select moisture-resistant MDF for bathrooms and kitchens.

4. How do wholesalers ensure MDF quality?

Check density, bonding strength, formaldehyde levels, and surface flatness.

5. Is MDF safe for indoor use?

MDF that meets E0/E1 or CARB standards is safe for interior environments.

6. Can MDF be customized in bulk?

Yes—suppliers can provide custom thickness, dimensions, lamination, and colors for large orders.

Final Thoughts

MDF remains one of the most practical, affordable, and stable materials for B2B buyers—especially wholesalers, distributors, and project contractors. Its consistency, machinability, and wide range of applications make it a reliable choice for large-scale commercial and residential projects. With the right supplier, MDF can significantly improve production efficiency and cost performance.